Over the years, Carlo Salvi has expanded its scope to meet the increasingly sophisticated demands of the aerospace sector. With decades of experience, the company has built a reputation for excellence in innovation and quality, investing in solutions that meet the market’s stringent precision and reliability requirements.

Next-level hot forming

Semi-hot forming is one of the most promising technologies for manufacturing high-performance aerospace components. This process allows the manufacturing of parts with extremely complex shapes while reducing costs and production times compared to traditional hot forming methods. Additionally, semi-hot forming enables the deformation of high-strength alloys and superalloys, minimizing the risk of cracks during forming – a critical aspect in aerospace manufacturing, where structural integrity is paramount.

This technology has several key features that define its effectiveness and application advantages:

• Intermediate temperature: The material is heated to a lower temperature than hot forming (typically between 500°C and 900°C, depending on the material).

• Reduced tool wear: The heat lowers material resistance, reducing stress on tools compared to cold forming.

• Higher precision compared to hot forging: Since temperatures are lower, thermal distortions are reduced, improving dimensional and surface quality.

Changing the game with induction heating

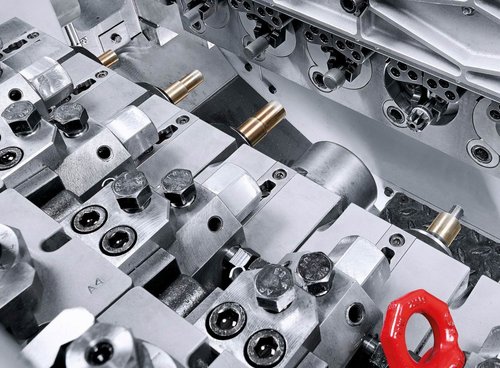

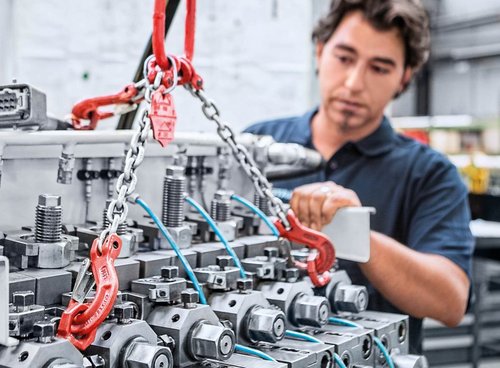

With the growing demands of the market, Carlo Salvi has directed its investments towards improving and optimizing its products. A crucial step in this process is the integration of an induction heating system into its machines, comprising an inductor, an optical pyrometer, and a chiller for cooling the die block and bedframe of the machine. These elements enhance thermal control during the high-temperature wire forming process.

The WS (Warm Series) machines represent one of the most promising solutions in the Italian market today. Converting cold forming machines into semi-hot forming solutions requires specific mechanical modifications to integrate the heating system, such as:

• Wire (or bar) heating via induction: This non-contact heating method places the inductor immediately before the cutting bushing, ensuring precise and controlled energy application.

• Preheating head with automatic positioning system: The coil’s position is regulated and monitored via the HMI, allowing “spotting”-type heating.

• Thermostat-controlled system for die block and baseplate: Initially, the system preheats the die block to minimize material waste. Once thermal balance is achieved, the block is adequately cooled to ensure repeatability of the produced parts.

• Protective and efficiency-enhancing safety measures: A specialized fireproof enclosure with brackets, covers, and protective elements for the coil, along with a pyrometer and temperature sensors, ensures system safety and functionality.

To further enhance process control, additional accessories are implemented, including an air-blowing system to keep the pyrometer clean and an automated heating management system. This includes the automatic removal of cold scrap via the automatic opening of the first finger and the built-in defective part separator. Safety is paramount, with the integration of a CO2 fire extinguishing system.

With the induction system installed, uniform and precise temperatures of up to 1000°C can be achieved, ensuring superior quality and increased efficiency. Temperature control is a crucial factor in semi-hot forming, as it enables optimal results with high-performance materials, reduces defects in formed parts, and preserves their mechanical properties, ensuring the durability and safety of the final product.

Large variety of materials

Among the most commonly used materials in semi-hot forming for aerospace applications are titanium alloys, aluminum alloys, high-strength stainless steels, and superalloys. These materials provide superior mechanical properties while maintaining the lightweight characteristics essential for aeronautical applications. Titanium alloys, in particular, are highly valued for their corrosion resistance. Inconel, despite its high density, is widely used in the aerospace sector due to its ability to withstand extreme thermal variations without significant dimensional changes, an essential feature for aerospace components.

Key applications include:

• Structural and covering elements for aircraft and engines: Bolts, special screws, fittings, and brackets.

• Turbine components: Turbine blades, discs, and rings made from superalloys such as Inconel 718.

• Titanium parts for frames and fastening systems: Lightweight components with high resistance to corrosion and elevated temperatures.

In conclusion, semi-hot forming offers numerous advantages, including:

• Precision and quality: Accurate temperature and deformation control allows for the production of components with very tight tolerances, essential in the aerospace industry.

• Production flexibility: The ability to feed machines with either wire or bar stock provides significant economic advantages for customers.

• Cost efficiency: Reducing defects during processing lowers costs associated with scrap and finishing operations.

• Complex geometries: Semi-hot forming enables the production of intricate shapes that would be difficult to achieve with traditional methods.

• Enhanced mechanical performance: This technology fully utilizes material properties, producing parts that are both lightweight and robust.

• Advanced geometries and applications: The ability to create complex geometries makes semi-hot forming particularly suited for aerospace components such as support structures, engine parts, and propulsion systems. These advanced geometries also contribute to reducing part weight, a crucial factor in optimizing aircraft performance and fuel consumption.

Commitment to innovation

Carlo Salvi continues to invest in research and development to enhance its semi-hot forming solutions, addressing the needs of an increasingly sophisticated aerospace market. Its ongoing commitment to innovation, combined with the ability to adapt to new challenges, makes the company a reliable partner for the production of high-quality, advanced components for the aerospace industry.

![[Translate to English:] Warmgepresse Muttern mit Maschinen von Hatebur]()

![]()

![]()

![]()

![]()

![]()

![]()

![drive_train.jpg Production of drivetrain components in automotive engineering on Hatebur hot presses]()

![Test]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![Test]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![[Translate to English:] Warmgepresse Muttern mit Maschinen von Hatebur](https://www.hatebur.com/fileadmin/_processed_/2/4/csm_Nuts_ade9b9280b.jpg)