-

Applicationszurück

-

Fastenerzurück

-

Nuts

![]()

Nuts

Our advanced machines offer the precision and efficiency required to produce a wide range of nuts for a wide variety of applications. -

Bolts & Screws

![]()

Bolts & Screws

Our machines are designed to produce bolts and screws with the highest accuracy and consistency to meet the needs of the automotive, aerospace, and other industries. -

Rivets

![]()

Rivets

With advanced technology and years of experience in the industry, we supply machines that ensure the highest quality and performance for the production of rivets. -

Automotive Fastener

![]()

Automotive Fastener

In the automotive industry, our machines are leaders in the production of fasteners that meet the high demands for strength, precision and efficiency. From screws and bolts to complex fastening systems, we provide solutions that meet our customers' production needs and increase their competitiveness. -

Aerospace Fastener

![]()

Aerospace Fastener

Our machines are specially designed to meet the demanding requirements of the aerospace industry and enable the production of high-precision and high-strength fasteners that meet the highest standards and ensure safety and performance. -

Oil & Gas Fastener

![]()

Oil & Gas Fastener

Our machines provide the flexibility and precision needed to produce fasteners for the demanding requirements of the oil and gas industry. From high strength nuts to specialty fasteners for offshore applications, the components produced meet the high standards and requirements of this industry. -

Construction Fastener

![]()

Construction Fastener

Our machines offer the versatility and performance required to produce fasteners for construction applications with the highest precision and reliability. From screws and bolts for building structures to fasteners for household appliances and sanitary applications, we offer solutions that meet specific requirements.

-

-

Automotivezurück

-

Drivetrain

![]()

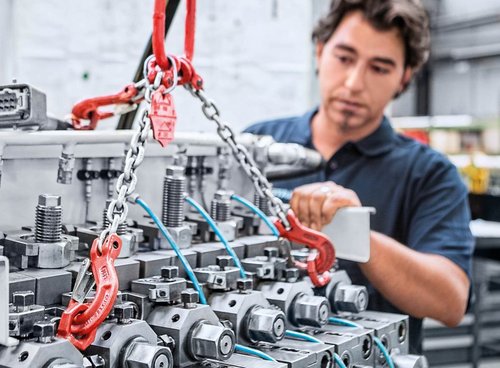

Drivetrain

Our systems are designed for precise and flexible production of drivetrain components in transmissions, differentials and constant velocity joints. They feature a robust design for long service life and ease of use. They feature a robust design for long service life and ease of use. -

Wheel Hubs

![]()

Wheel Hubs

Our machines offer the precision and performance required for the production of wheel hubs that meet the stringent requirements of the automotive industry. -

Cam Lobes

![]()

Cam Lobes

Our advanced machines provide the precision and efficiency required to produce cams for assembled camshafts that ensure optimum performance and fuel efficiency in automotive applications. -

ICE Parts

![]()

ICE Parts

We supply machine solutions that meet the high demands of the automotive industry and enable reliable production of ICE parts. -

BEV Parts

![]()

BEV Parts

With our innovative machines, we offer efficient manufacturing solutions for the production of parts for battery-powered electric vehicles and support the automotive industry in the transition to electric mobility. Our systems stand for the highest quality, performance, durability and ease of use. -

Safety parts & Interior

![]()

Safety parts & Interior

Our machines offer the flexibility and precision required for the production of safety components and interior parts. With our systems, we support automotive manufacturers in the production of high-quality and safe vehicles that meet the requirements of modern automotive standards. -

Automotive Fastener

![]()

Automotive Fastener

In the automotive industry, our machines are leaders in the production of fasteners that meet the high demands for strength, precision and efficiency. From screws and bolts to complex fastening systems, we provide solutions that meet our customers' production needs and increase their competitiveness.

-

-

Bearingzurück

-

Ball bearings

![]()

Ball bearings

With our advanced machine technology, ball bearing rings can be produced with the highest precision and material efficiency. -

Roller bearings

![]()

Roller bearings

Our machines provide the accuracy and reliability required to produce inner and outer rings for rolling bearings used in a wide range of applications, from automotive to machinery. -

Wheel Hubs

![]()

Wheel Hubs

Our machines offer the precision and performance required for the production of wheel hubs that meet the stringent requirements of the automotive industry.

-

-

Aerospacezurück

-

Pins, Bolts, Studs

![]()

Pins, Bolts, Studs

With our leading technology and precision, our machines enable the production of pins, bolts and studs that meet the most stringent aerospace requirements. -

Nuts, Inserts

![]()

Nuts, Inserts

Our machines provide the accuracy and efficiency required for the production of nuts and inserts used in the aerospace industry. -

Rivets

![]()

Rivets

With advanced technology and years of experience in the industry, we supply machines that ensure the highest quality and performance for the production of rivets. -

Aerospace Fastener

![]()

Aerospace Fastener

Our machines are specially designed to meet the demanding requirements of the aerospace industry and enable the production of high-precision and high-strength fasteners that meet the highest standards and ensure safety and performance.

-

-

Oil & Gaszurück

-

Flanges

![]()

Flanges

With our advanced technology, our machines enable the precise production of flanges that meet the stringent requirements of the oil and gas industry. -

Union nuts

![]()

Union nuts

Our machines offer the precision and reliability required for the production of union nuts used in the oil and gas industry. -

Fittings

![]()

Fittings

Our machines provide the accuracy and efficiency required for the production of fittings used in the oil and gas industry to ensure reliable connection of pipes, valves and other components. -

Oil & Gas Fastener

![]()

Oil & Gas Fastener

Our machines provide the flexibility and precision needed to produce fasteners for the demanding requirements of the oil and gas industry. From high strength nuts to specialty fasteners for offshore applications, the components produced meet the high standards and requirements of this industry.

-

-

Construction & Household Goodszurück

-

Fittings for plumbing

![]()

Fittings for plumbing

With our leading technology, our machines enable the production of high-quality fittings for plumbings that meet the stringent requirements of the construction industry. -

Construction Fastener

![]()

Construction Fastener

Our machines offer the versatility and performance required to produce fasteners for construction applications with the highest precision and reliability. From screws and bolts for building structures to fasteners for household appliances and sanitary applications, we offer solutions that meet specific requirements. -

Fastener for furniture

![]()

Fastener for furniture

Our machines offer the precision and efficiency required to produce fasteners for furniture that meet the demanding requirements of this industry. -

Special nuts

![]()

Special nuts

Our machines offer the accuracy and reliability required for the production of special nuts used in the construction and household goods industries.

-

-

-

Machines & Accessorieszurück

-

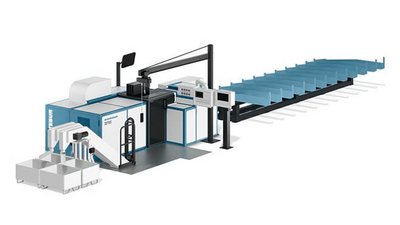

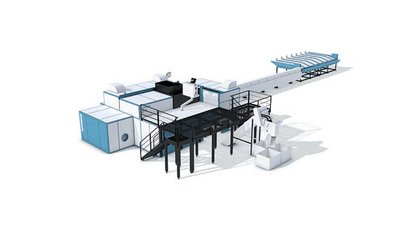

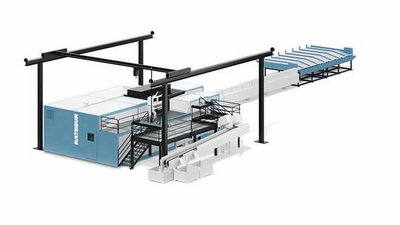

COLDmaticzurückCOLDmatic

-

1 Die 2 Blow Headerzurück1 Die 2 Blow Header

-

CS 001CS 001

![]()

-

CS 002CS 002

![]()

-

CS 003CS 003

![]()

-

CS 7120 DLCS 7120 DL

![]()

-

CS 7148CS 7148

![]()

-

CS 8120 DLCS 8120 DL

![]()

-

CS 005CS 005

![]()

-

-

2 Die 4 Blow Headerzurück2 Die 4 Blow Header

-

Progressive HeaderszurückProgressive Headers

-

HOTmaticzurückHOTmatic

-

-

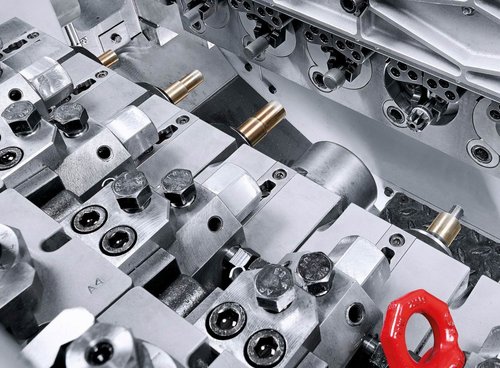

Tools & Processes

-

Service & Support

-

Company