Following an extensive modernization of the press, the managing team are delighted to have less downtime, significantly longer maintenance intervals and a much wider product range. This accommodates resourceful toolmakers who also produce smaller batch sizes on the press and enjoy testing what is physically possible.

“By installing a new hydraulic clutch and brake, as well as a servo infeed and hydraulic bar stop, we’ve not only modernized our AMP 70, but have also taken productivity to a new level after 18 years of production,” emphasizes Florian Mandl, Production Manager at PENN GmbH. “We’re particularly impressed by the considerably lower level of maintenance,” adds his colleague and Head of Operational Engineering, Peter Schäffel. Since 2007, the Austrian toolmaking and forging specialists have used their Hatebur HOTmatic AMP 70 to produce high-quality, hot-formed steel components for various industries. It was high time for a modernization, especially because the flywheel shaft bearing block with a pneumatic clutch and brake showed significant signs of wear and required regular maintenance. Moreover, the additional upgrade to a servo-hydraulic infeed and bar stop represents a milestone in higher part quality.

Workers at PENN GmbH value the wide range of parts that can be produced on the reliable hotformer. In addition to producing traditionally high quantities of parts for the automotive industry, they have also been manufacturing quality parts for the construction industry and railway industry, as well as for trucks and agricultural vehicles, for a number of years. As part of this, the experts at PENN GmbH have specialized in increasingly complex components that can also be produced in smaller batches from 15,000 to 20,000, which certainly marks a unique selling point. Employees at PENN GmbH were quickly impressed when the experts at Hatebur stated that the press could still be upgraded with state-of-the-art technology after many years of production and could still produce parts successfully for many more years. Ultimately, users were thoroughly impressed by the quality and reliability of the AMP 70.

Meticulously planned modernization processes

As a result, in autumn 2023, the company started to replace the pneumatic clutch and brake with the new, current hydraulic version. This was primarily intended to prevent the high level of wear on the pads and toothing of the clutch and brake, as well as to reduce the effect of fouling over time. In recent times, the effort and costs of maintenance have been considerable.

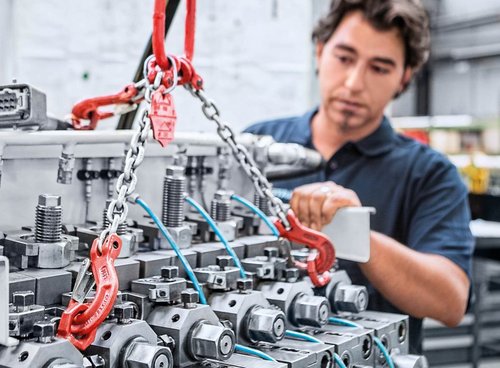

The hydraulic clutch and brake were first developed for the Hatebur HM 75. When it quickly became clear that the old weak points were virtually eliminated, developers at Hatebur converted the system for use in the AMP 70. This means that the clutch and brake have their own hydraulic unit. The sintered metal pads are lubricated and cooled by the hydraulic oil. In addition, a modern modular control system with integrated standstill monitoring ensures safe operation. After fitting the clutch and brake, the oil collecting ring was installed, the hydraulic device was set up, the lines were routed and the electrical system was connected. “What’s good about the upgrade is that it’s not necessary to rework the flywheel or pinion shaft,” emphasizes Hatebur Project Manager Oliver Borgolte. After just four weeks spent solely converting the machine, it was already possible to start up production again in December 2023.

Quick and long-term improvements

The measures immediately took effect. The machine engages much more smoothly and therefore reduces the amount of force on the toothing. There are virtually no more signs of wear on the sintered metal pads. In addition, the active cooling system makes the system robust against thermal overload. The brake pads are no longer fouled and there is hardly any wear. Unexpected downtime due to problems with the clutch or brake are things of the past. “This allows you to reliably plan production,” says Schäffel, who also drew the following pleasing interim conclusion in May 2024 – “we’re delighted that the machine virtually no longer stands still anymore and that almost no maintenance is required.” For the second modernization step – installing a new servo-hydraulic infeed and bar stop – Hatebur no longer needs to impress users.

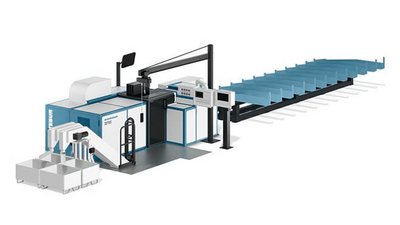

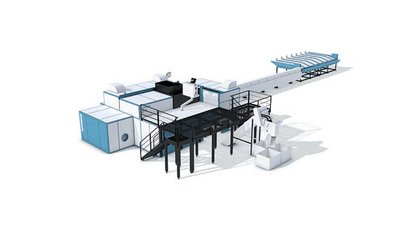

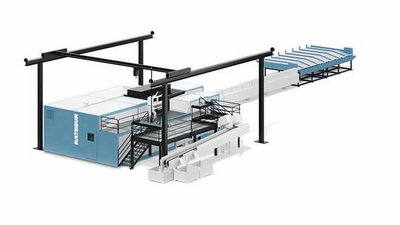

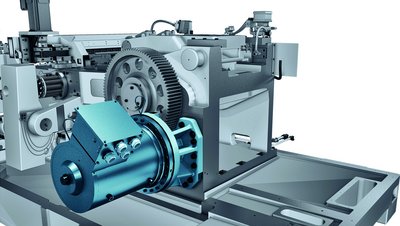

With the Hatebur HOTmatic AMP 70 with four forming stations and a press load of 15,000 kN, the Austrianbased company produces 50 to 80 forgings per minute in a fully automated way with diameters up to 145 millimeters and with workpiece weights of between 400 grams and 5 kilograms. What’s more – thanks to the toolmakers’ ingenuity – they can even achieve 140 parts per minute by forging mechanical engineering components with duplicates that are separated in the fourth operation stage. The servo-hydraulic infeed and bar stop should now ensure higher, reproducible process reliability and a significant increase in efficiency for the forming process.

Precisely feeding in and positioning bars

The highly precise servo infeed feeds the AMP 70 with bar material with diameters from 36 to 75 millimeters. This is ensured by infeed rollers powered by two servo motors. Given that there is no need for the drive mechanics and freewheel unit, or for them to be replaced, there is minimal mechanical wear and maintenance. Accordingly, the machine operates much more reliably. Employees at PENN GmbH appreciate the automatic bar withdrawal and the function that removes the hot bar from the machine.

And, of course, they enjoy all of the benefits of the servo infeed. This means that the infeed stroke and cut-off length can be continuously adjusted during the production process. The infeed stroke no longer needs to be manually adjusted but is controlled via the control desk. This considerably reduces the set-up time for tool changes. Given that the infeed length is always precise, the volume of cut-offs is much more constant. During the bar transition, the infeed position can be optimally controlled and therefore wedges can be avoided at the leading edge or end of bars.

Eliminating shear fractures, wedges and flaking

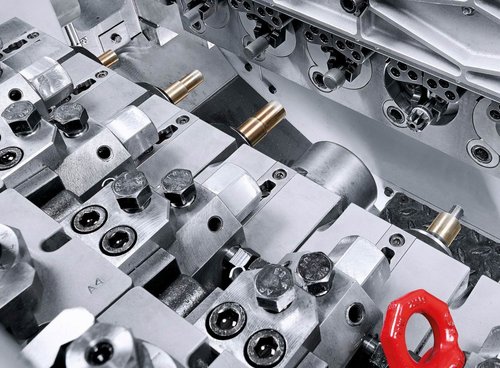

The glowing steel bars are fed in precisely and must be accurately sheared off. The servo-hydraulic bar stop from Hatebur constitutes a big step forward in this regard because it considerably improves the surface quality of the shearing surface. In the past, the cut-off may have been slightly pitched and stood at an angle during the shearing process. The two sheared surfaces were therefore not completely parallel. More serious was when the shearing turned into a crack at the end of the process, meaning that the material was broken, rather than being cleanly sheared. Furthermore, a type of scaling occurs, as well as sometimes a type of fracture known as a wedge.

Optimal cut-offs for higher part quality

The servo-hydraulic bar stop substantially reduces both the pitch and the angle of the cut-off. Both surfaces are practically parallel. Moreover, scaling only rarely occurs. “There are no longer any wedges either,” assures Schäffel. The results are impressive. “The break-outs are reduced considerably or are removed completely. All of the parts are the same and it is safer and easier to transport them between the forming stations.” The process cannot be seen with the naked eye since, depending on the diameter of the bar and speed of the machine, the process lasts just 60 to 100 milli-seconds. Hatebur Product Manager Carsten Sieber explains, “at this speed, only a servo-hydraulic drive can provide the necessary dynamics and power density in the smallest of spaces.”

Identifying and correcting changes in position at the micrometer level

To achieve the best possible shearing quality, operators can choose position or force control of the servohydraulic bar stop. At the end of the infeed process, the bar meets the bar stop. The latter is compressed by several hundredths of a millimeter, thereby deviating from the setpoint position. This intended deviation is identified by the high-resolution stroke measuring system on the differential cylinder with an accuracy of 1 micrometer, at which point the control unit instantaneously offsets the position of the bar stop via the servo valve. This position control keeps the effective distance between the blade and the bar stop constant throughout the shearing process.

Immediately after shearing starts, the control system switches to force control with position monitoring. This results in a buildup of counteracting force that presses the future cut-off against the remaining bar, preventing pitching or angling. Just before the shearing process ends, the cylinder switches back to position control. The cut-off is then moved into the first forming station by the shearing blade with cut-off holder.

Back to its core competence after modernization

Workers at PENN GmbH are satisfied with the modernization, which was completed in November 2024. “With the modernized AMP 70, we’re now focusing again on testing what is physically possible,” say a delighted Mandl and Schäffel in unison.

![[Translate to English:] Warmgepresse Muttern mit Maschinen von Hatebur]()

![]()

![]()

![]()

![]()

![]()

![]()

![drive_train.jpg Production of drivetrain components in automotive engineering on Hatebur hot presses]()

![Test]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![Test]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![[Translate to English:] Warmgepresse Muttern mit Maschinen von Hatebur](https://www.hatebur.com/fileadmin/_processed_/2/4/csm_Nuts_ade9b9280b.jpg)